The company was founded by PV in 1959.

He had two objectives. While he pursued a personal childhood dream to be an engineer and "own machines", the broader vision was to start a business in a remote village and propel it into prosperity.

Pallikaranai was a tiny hamlet, hundreds of years old, largely forgotten by the world, across the Pallikaranai Marsh from Velacherry. It had no running water supply and no electricity. People there lived pretty much they had for several hundred years.

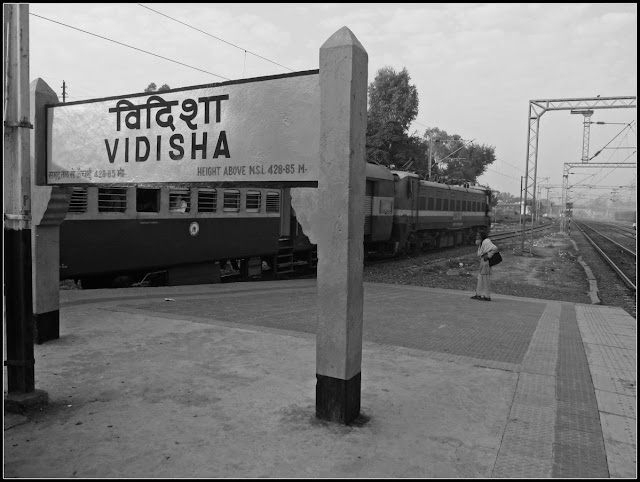

This is the only photo available of the site of the company when it was built in 1966.

During the monsoon, parts of the track were submerged in the Marsh and water snakes would often cross it.

As the company grew and started employing people from across

the marsh, bus services were started by the then PTC at the company's request

in 1972.

PV succeeded in his dream in large measure.

PV came across the land quite by chance. Originally, he had

picked a plot in Velacherry and then realized it was on the fringes of the

great 400 hectare Pallikaranai Marsh, hardly conducive to a stable foundation.

The amazing thing was that at the other end of the Marsh road he found this

plot of land with probably the best possible soil for the foundations of a

factory – rocky murram. GMT possibly stands on the only plot for kilometres

around, which has this soil, so close to a giant wetland.

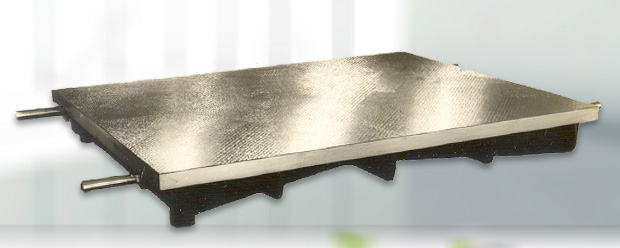

Here’s what Murram looks like; compare it with the next

picture which is marshy soil.

For a precision engineering factory, vibrations due to

operation of machines and other external influences have to be minimum.

The factory used to be lit by tube light, the floor was dark

with oil and coolant soaked in from innumerable spills from the machining and

many of trial assemblies of special purpose machines, and the air was redolent

of the smells of machine oil, coolant and grease.

Purchase of parts for machines was an enormous challenge.

Nothing was available locally in Pallikaranai and all parts had to be purchased

from Mount Road or George Town 30 kilometers away, and sometimes from Bombay or

Bangalore.

So, purchase of simple parts often took several days… and

then the excitement of each installation merited heated discussions and

arguments, with the whole team pitching in with their own ideas on everything

about the machine design, the commissioning problems and customer feedback.